Strona główna " Produkty " PVC Pallet of Concrete blocks

The pallet of concrete block is a pallet used to place the concrete blocks after the molds are demoulded in the process of pressing and forming the cinder blocks. According to the different raw materials, they can be divided into wooden pallets, bamboo pallets and PVC Pallet, glass fiber pallet (GMT Pallet).

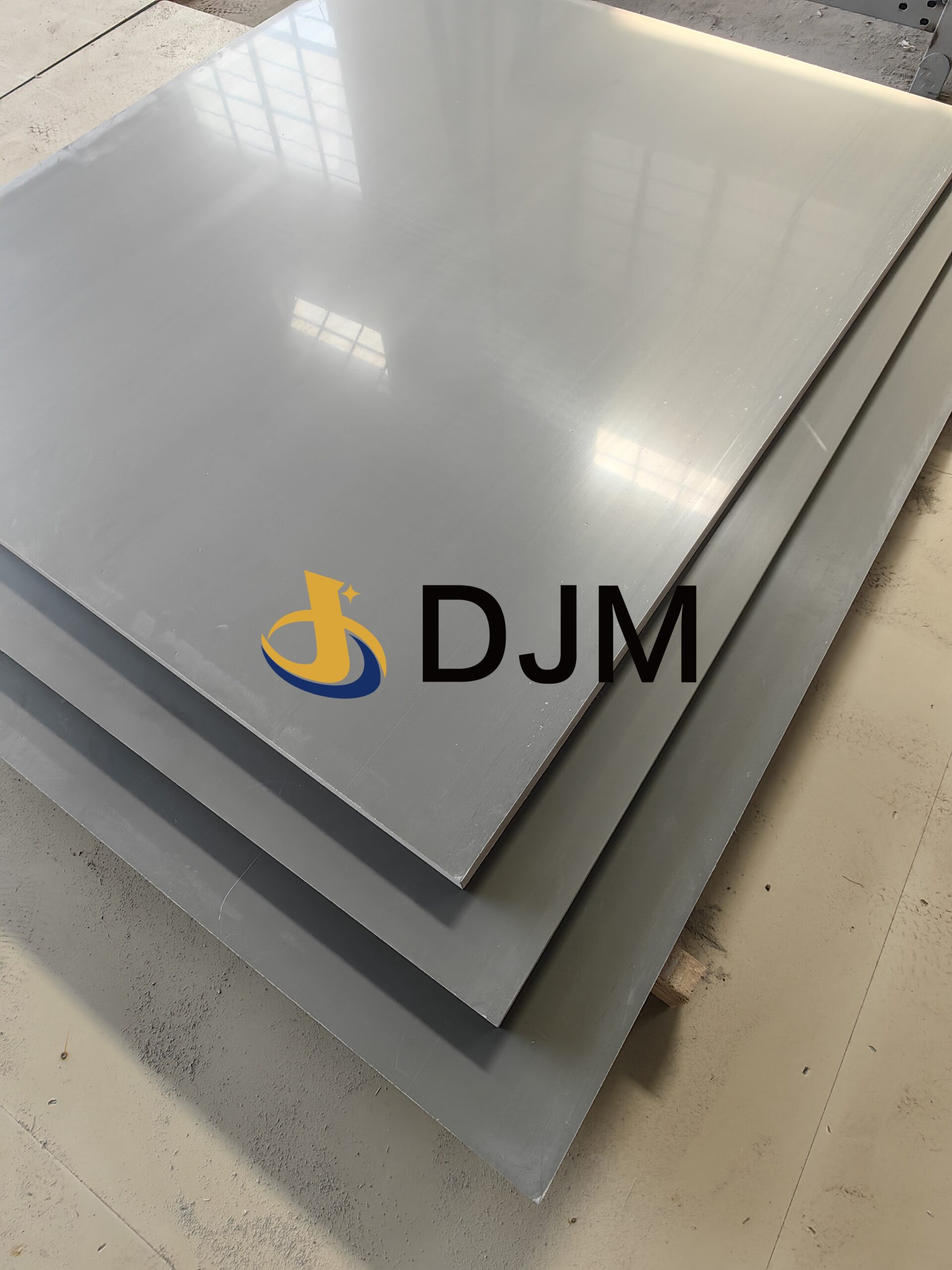

PVC pallets use PVC resin powder as raw material, add certain proportion of anti-aging agents, lubricants, antioxidants, etc., extruded by electric heating, and then cut to produce pallets of various specifications.

The quality of PVC pallets is uneven, and the prices are high or low. When you buy PVC pallets, check and compare more. Remember: cheap quality is definitely not good, bad quality is easy to crack.

The size of the block pallet is determined by the model of the brick machine. When you determine the model of the brick machine you choose, we can determine the size of the pallet.

At present, the most commonly used on the market are four kinds of pallets, wooden pallets, bamboo plastic pallets, PVC pallets, and GMT fiberglass pallets. I have a detailed introduction above.

If your budget is relatively low, you can choose wooden pallets and bamboo rubber pallets. In terms of price, wooden pallets have the lowest price, followed by bamboo rubber pallets. The price of PVC pallet and GMT fiberglass board is similar. The disadvantages of wooden pallets and bamboo rubber pallets are that they are prone to corrosion and cracking and have a relatively short service life.

Due to the uneven materials used in PVC pallets, the quality of PVC pallets is very different. In general, relatively low-priced PVC panels have poorer materials, and this pallet is easy to break. And the same volume of pallets, PVC pallets have the largest weight, increasing labor costs for workers.

GMT fiberboard is the third generation pallet, which is currently the best pallet. This pallet has the best performance and can theoretically be used for more than 8 years. The price of fiberglass board is not as high as that of PVC board. Very suitable for use in the production line of brick machines.

The quantity of concrete blocks on block machine pallet is different from the block machine models.

For concrete blocks size: 8x8x16inch, 390x190x190mm, or 400x200x200mm, the quantity are as bellow:

Model QT 4 series block machine can moulding 4 pcs of concrete blocks.

Model QT 5 series block machine can moulding 5 pcs of concrete blocks.

Model QT 6 series block machine can moulding 6 pcs of concrete blocks.

Model QT 8 series block machine can moulding 8 pcs of concrete blocks.

Model QT 10 series block machine can moulding 10 pcs of concrete blocks.

The pallet of concrete block is a pallet used to place the concrete blocks after the molds are demoulded in the process of pressing and forming the cinder blocks. According to the different raw materials, they can be divided into wooden pallets, bamboo pallets and PVC Pallet, glass fiber pallet (GMT Pallet).

Masz pytania dotyczące naszych produktów?

Nie wahaj się z nami skontaktować. Specjaliści ds. produktów DJM z przyjemnością udzielą pomocy i zapewnią profesjonalne i niezawodne rozwiązania, które pomogą rozwiązać różne problemy.

Bezpłatna wycena

Zapewnienie jakości

Nasza firma jest przedsiębiorstwem high-tech integrującym badania i rozwój sprzętu, produkcję, sprzedaż i obsługę posprzedażną.

Copyright © 2024 Quanzhou DJM Equipment Co., Ltd. Wszelkie prawa zastrzeżone.